SBR Process Description The Sequencing Batch Reactor (SBR) process has been extensively used in Europe and the United States in the past two decades. One of the obstacles in the acceptability of SBR process has traditionally been the need for precise, automated and reliable control of various stages of the process. Recent developments in the programmable logic controller (PLC) technology, however, have made the control of an SBR process readily achievable.

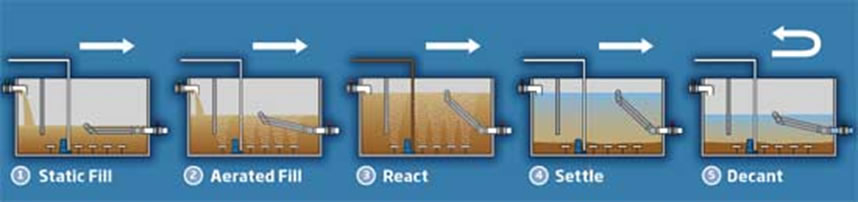

The SBR process is an activated sludge process in which the sewage is introduced into a Reaction Tank (or SBR Tank), one batch at a time. Wastewater treatment is achieved by a timed sequence of operations which occur in the same SBR Tank, consisting of filling, reaction (aeration), settling, decanting and when needed sludge wasting.

The various stages in the sequence are as follows:

Stage 1: Filling

During this stage the SBR Tank is filled with the influent wastewater. In order to maintain suitable F/M (food to microorganism) ratios, the wastewater should be admitted into the tank in a rapid, controlled manner. This method functions similarly to a selector, which encourages the growth of certain microorganisms with better settling characteristics.

Stage 2: Reaction

This stage involves the utilization of biochemical oxygen demand (BOD) by microorganisms. The length of the aeration period and the sludge mass determines the degree of treatment. The length of the aeration period depends on the strength of the wastewater provided for in the treatment.

Stage 3: Settling

During this stage, aeration is stopped and the sludge settles leaving clear, treated effluent above the sludge blanket. Duration for settling varies from 45 to 60 minutes depending on the number of cycles per day.

Stage 4: Decanting

At this stage of the process effluent is removed from the tank through the decanter, without disturbing the settled sludge.

Stage 5: Sludge Wasting

Excess activated sludge is wasted periodically during the SBR operation. As with any activated sludge treatment process, sludge wasting is the main control of the effluent quality and microorganism population size. This is how the operator exerts control over the effluent quality by adjusting the mixed liquor suspended solids (MLSS) concentration and the Mean Cell Residence Time (MCRT) or Sludge retention time (SRT).